Sed ut perspiciatis unde natus error voluptatem accusantium doloremque explicabo...

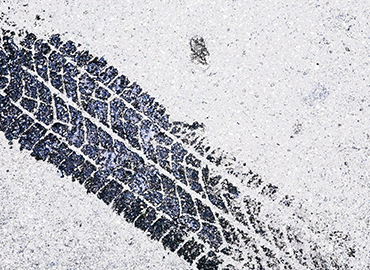

The ASPHALT & BITUMEN

ARE HIGH-QUALITY INDUSTRIAL MATERIALS

Efficiently Used For Paving Roads Surfaces, Waterproofing And Sealing Roofs And Boats And To Coat Buildings.

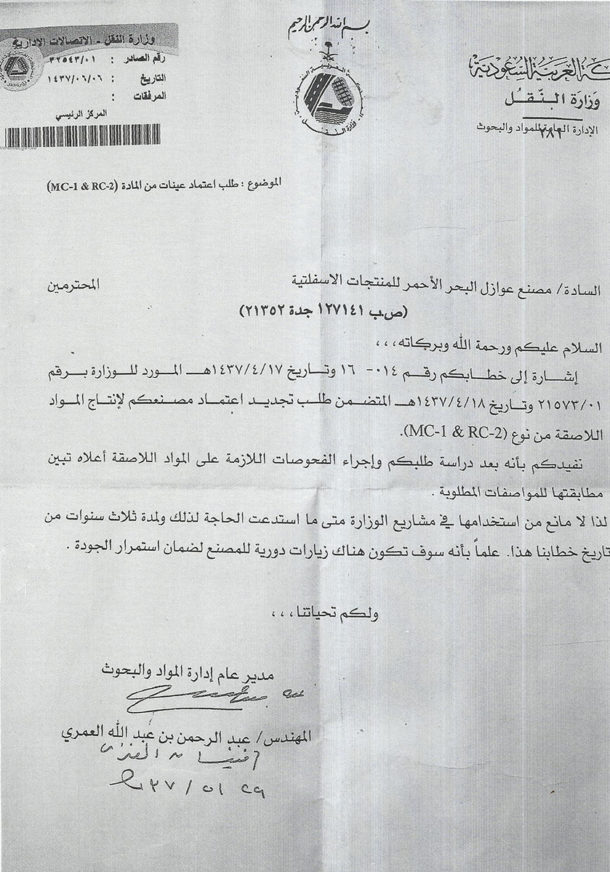

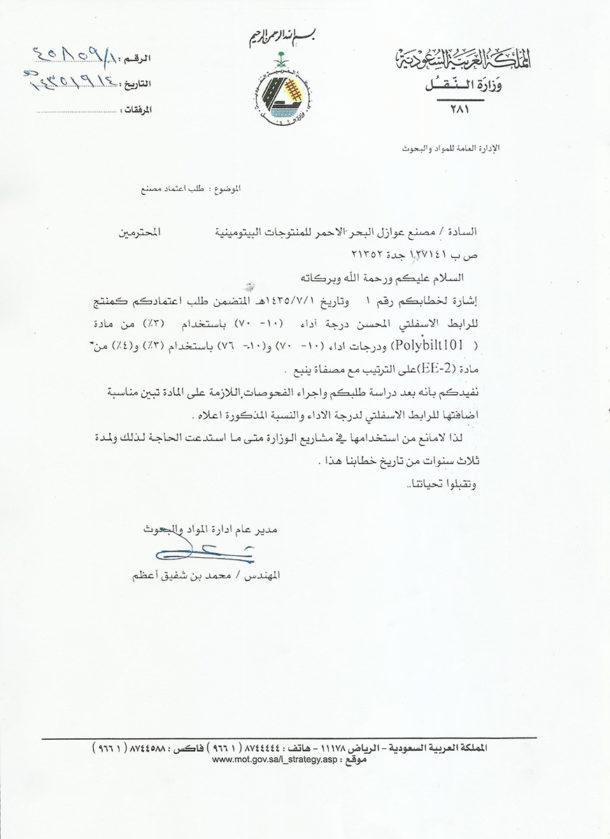

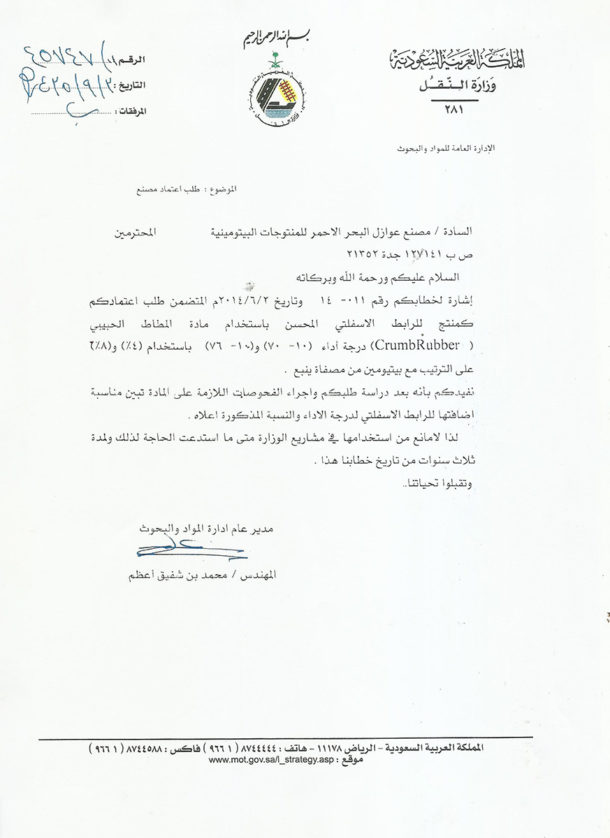

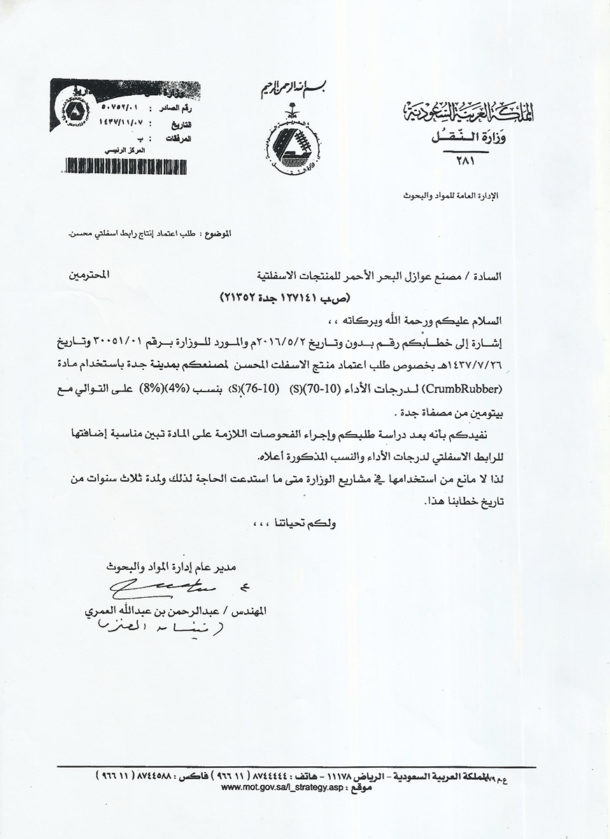

The Red Sea Waterproofing Factory.

Was Established In 2012 And It’s Considered To Be The Newest Factory In The Region.

View More

The Manufactory Products

ARE HIGH-QUALITY MATERIALS FOR ALL PURPOSES

RSW Produces All Types Of Products With The Bituminous Base Which Is Widely Used For Infrastructure Projects.

View More